No products in the cart.

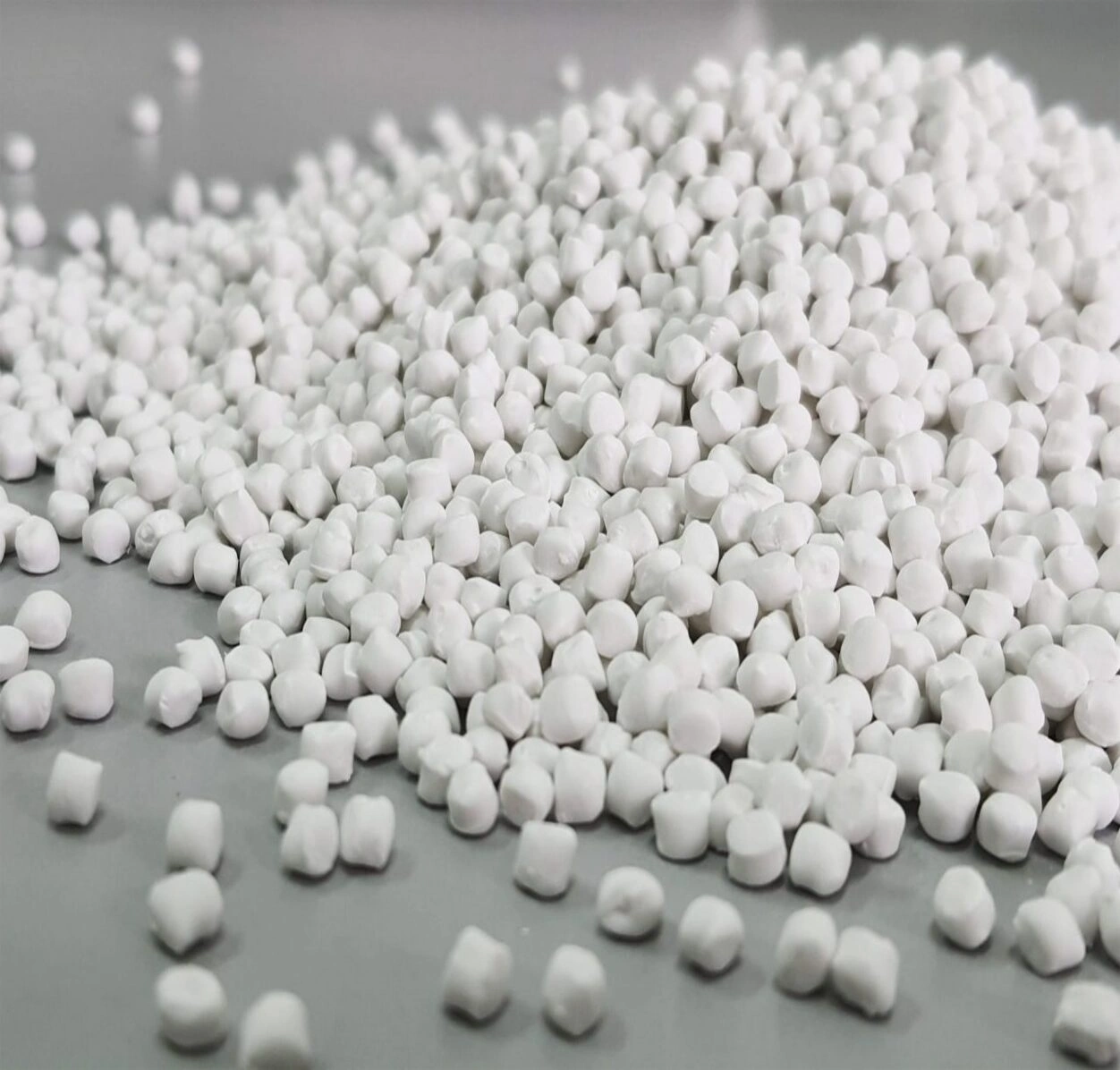

White Masterbatch

Rated 0 out of 5

0 customer reviews

Category: Masterbatch

White Masterbatch

- White Masterbatch is developed with ultras white & uktras fine TiO2 to provide better properties to the products.

-

White masterbatch provides maximum whiteness and opacity to plastic products. Manufacturers create it using high-quality rutile titanium dioxide, polyolefin resin, and special additives. This formula ensures it meets strict global standards.

-

It is widely used in packaging materials, pipes, films, and sheets. It offers a cost-effective solution for achieving a consistent, uniform white color without additional pigments.

-

Companies can also customize it to meet specific brightness requirements. Therefore, it has become a vital tool in the plastic industry.

-

The key advantages include very high opacity, high brightness, and an attractive shine. It also helps eliminate several production issues. Furthermore, its strong durability reduces maintenance needs and lowers replacement costs.

-

It is suitable for many applications. These include Film, Injection, Pipe and Profile Manufacturing, and other processes. Plastic appliances also benefit from its consistent quality.

-

Industries such as Packaging, Automotive, Construction, and Household Appliances rely on white masterbatch for performance and reliability.

-

In the Packaging Industry, white masterbatch creates clean, bright plastic bags, containers, films, and other materials. This clean appearance improves the overall attractiveness of products.

-

The Automotive Industry uses white masterbatch for dashboards, door panels, and various components. These parts not only function well but also maintain a high aesthetic appeal.

-

For Household Appliances, we manufacture cost-effective white masterbatches suited for bottles, caps, closures, buckets, and containers. A uniform white finish ensures a high-quality look.

-

In the Building and Construction Industry, manufacturers use white masterbatch for pipes, fittings, roofing sheets, and similar products.

-

It ensures a durable, consistent, and visually appealing surface, while meeting tough quality standards.

To order send WhatsApp

| Color | White |

|---|---|

| Application | Blow Molding, Film, Injection, Raffia |

| CaCO3 Content | 30% up to 50% |

Reviews

0

Rated 0 out of 5

0 customer reviews

5

0

4

0

3

0

2

0

1

0

Be the first to review “White Masterbatch” Cancel reply

Related Products

Black Masterbatch

Black masterbatch containing carbon black, virgin resin, and other special additives offer an effective solution for incorporating carbon black in […]

recent view product

PP Compound

PP Compound is an Economical Master Batch Based on Very Fine Particle Size Coated Calcium Carbonate in Polyolefin Which Contributes […]

Color Masterbatch

Color masterbatch is a concentrated mixture of pigments or dyes, combined with a carrier resin. It’s used in the plastics […]

Uncoated Calcium Carbonate

Uncoated calcium carbonate powder is a versatile material that offers numerous benefits across various industries.- It has excellent properties such as […]

Coated Calcium Carbonate

Coated calcium carbonate powder is a specially treated form of ground calcium carbonate (GCC) where each particle is coated with a […]

PE Compound

PE Compound is an Economical Master Batch Based on Very Fine Particle Size Coated Calcium Carbonate in PE Which Contributes […]

There are no reviews yet.