No products in the cart.

PE Compound

Rated 0 out of 5

0 customer reviews

Category: Calcium Carbonate Compounds

PE Compound

- PE Compound is an Economical Master Batch Based on Very Fine Particle Size Coated Calcium Carbonate in PE Which Contributes to Extrusion Process Stability and Improved Output.

- It supports PE-colored film production due to its strong anti-blocking properties and effective hiding power.

- It is a cost-effective masterbatch formulated with ultra-fine coated calcium carbonate in PE.

- This composition enhances extrusion process stability and boosts output.

- Manufacturers use it as an economical alternative to TiO₂ in specific injection and molding applications.

- It works well with polypropylene raffia systems.

- PE has numerous applications across various industries due to its desirable properties.

- APPLICATIONS:

• Blow Molding.

• Blown Film.

– Very Thin Films.

– Agricultural Films.

– Diaper Films.

• Injection Molding. - PE Compounds refer to various formulations of Polyethylene (PE), each designed to meet specific performance, processing, or end-use requirements.

- PE Compound allows easy dilution and uniform mixing, making it ideal for direct feeding through automatic dosing units or manual pre-blending.

- DOSAGE: Use between 1% and 50%, depending on the final application.

- LIFETIME AND STORAGE: Use within 12 months; avoid storing in very humid areas or exposing the material to direct sunlight for long periods.

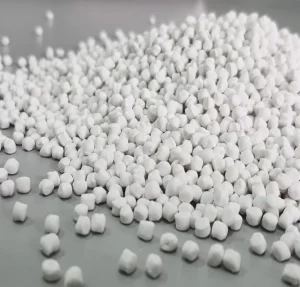

- PRODUCT FORM AND PACKAGING: White Color Master Batch in Pellet Form Packed in PP Bags Of 25 Kg Each.

To order send WhatsApp

| Color | Pellets Have a White Appearance |

|---|---|

| Packaging | White Color Master Batch in Pellet Form Packed in PP Bags Of 25 Kg Each. |

Reviews

0

Rated 0 out of 5

0 customer reviews

5

0

4

0

3

0

2

0

1

0

Be the first to review “PE Compound” Cancel reply

recent view product

PP Compound

PP Compound is an Economical Master Batch Based on Very Fine Particle Size Coated Calcium Carbonate in Polyolefin Which Contributes […]

Coated Calcium Carbonate

Coated calcium carbonate powder is a specially treated form of ground calcium carbonate (GCC) where each particle is coated with a […]

Uncoated Calcium Carbonate

Uncoated calcium carbonate powder is a versatile material that offers numerous benefits across various industries.- It has excellent properties such as […]

White Masterbatch

White Masterbatch is developed with ultras white & uktras fine TiO2 to provide better properties to the products. White masterbatch […]

PE Compound

PE Compound is an Economical Master Batch Based on Very Fine Particle Size Coated Calcium Carbonate in PE Which Contributes […]

There are no reviews yet.