No products in the cart.

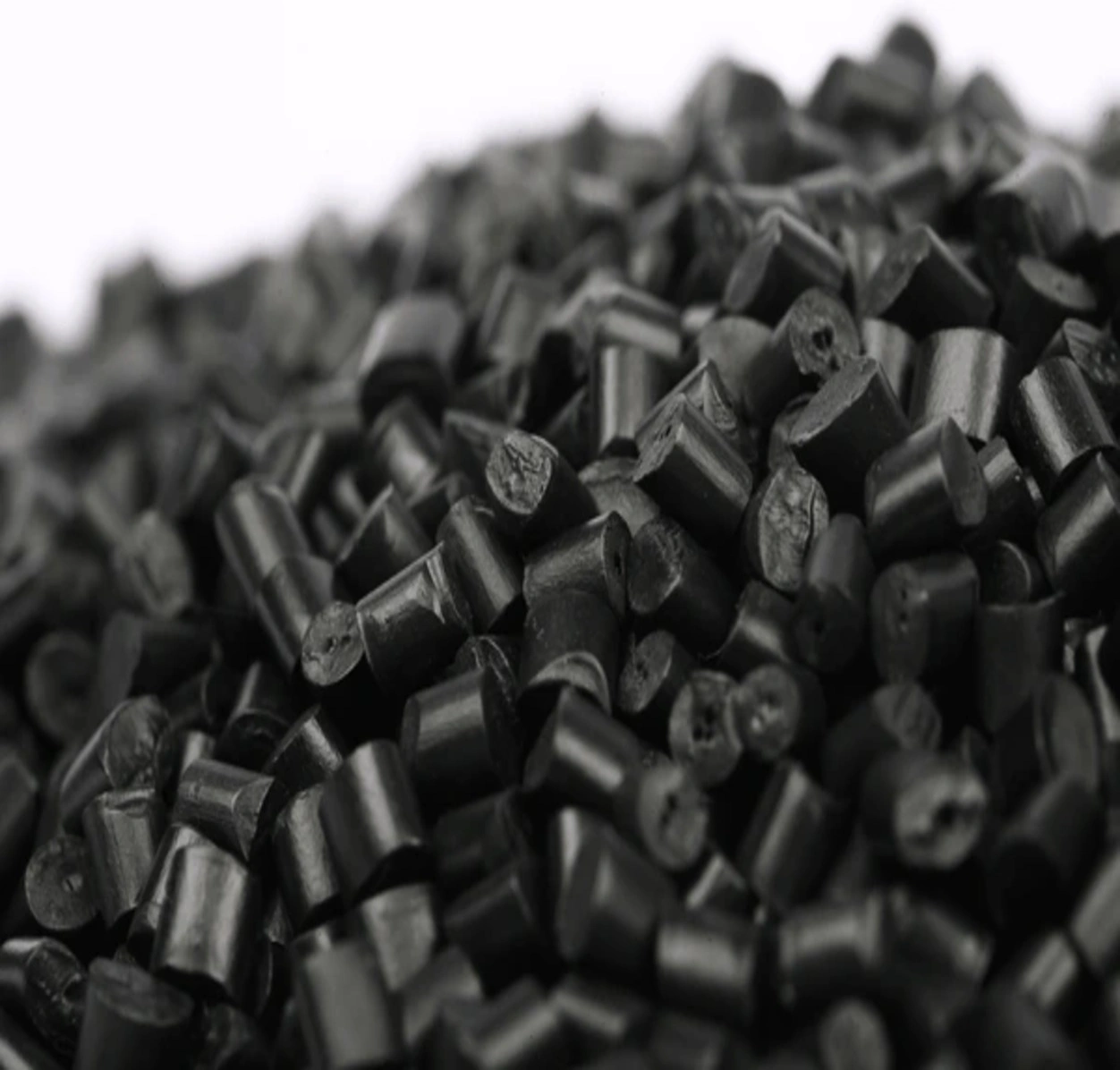

Black Masterbatch

Rated 0 out of 5

0 customer reviews

Category: Masterbatch

Black Masterbatch

- Black masterbatch containing carbon black, virgin resin, and other special additives offer an effective solution for incorporating carbon black in thermoplastics.

-

It’s plays a key role in various industries, especially the plastics industry, by providing essential color and functional properties to a wide range of plastic products.

-

It is highly versatile and can be used with different types of resins, including polyethylene (PE), polypropylene (PP), and others.

-

This adaptability makes it suitable for applications ranging from packaging to automotive parts.

-

In the construction sector, it is vital in producing materials such as pipes and cables.

-

In agriculture, it contributes to manufacturing irrigation pipes, greenhouse films, and mulching films.

-

Its UV resistance and durability make it ideal for products exposed to sunlight and harsh weather conditions.

-

Key applications of black masterbatch include packaging, the automotive industry, construction, consumer goods, and agriculture.

-

From household appliances to electronic devices, it is used to produce a variety of consumer goods.

-

Manufacturers prefer black masterbatch because of its versatility and cost-effectiveness.

-

Black masterbatch provides a reliable solution for achieving high-quality, durable, and visually appealing products.

-

Its performance is outstanding, offering high concentration, brightness, durability, high-temperature resistance, and ease of processing.

- Major application areas of this Masterbatch are blow molding, injection molding, HDPE pipes, monofilaments, Film extrusion etc.

To order send message

| Color | Black |

|---|---|

| Application | Blow Molding, Film, Injection, Raffia |

| CaCO3 Content | 35% up to 55% |

Reviews

0

Rated 0 out of 5

0 customer reviews

5

0

4

0

3

0

2

0

1

0

Be the first to review “Black Masterbatch” Cancel reply

Related Products

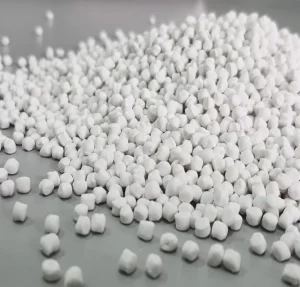

White Masterbatch

White Masterbatch is developed with ultras white & uktras fine TiO2 to provide better properties to the products. White masterbatch […]

recent view product

Color Masterbatch

Color masterbatch is a concentrated mixture of pigments or dyes, combined with a carrier resin. It’s used in the plastics […]

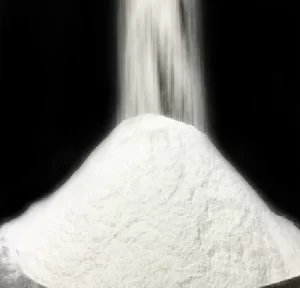

Talcum Powder

Talcum powder is a finely ground form of talc, a naturally occurring mineral composed mainly of magnesium, silicon, and oxygen. […]

Uncoated Calcium Carbonate

Uncoated calcium carbonate powder is a versatile material that offers numerous benefits across various industries.- It has excellent properties such as […]

Coated Calcium Carbonate

Coated calcium carbonate powder is a specially treated form of ground calcium carbonate (GCC) where each particle is coated with a […]

White Masterbatch

White Masterbatch is developed with ultras white & uktras fine TiO2 to provide better properties to the products. White masterbatch […]

There are no reviews yet.