No products in the cart.

Calcium carbonate is widely used in the paper industry as a key ingredient and filler material. Its unique properties make it an essential component in various stages of paper production, from initial fiber processing to the final paper product.. Here are some of the primary uses of calcium carbonate in the paper industry:

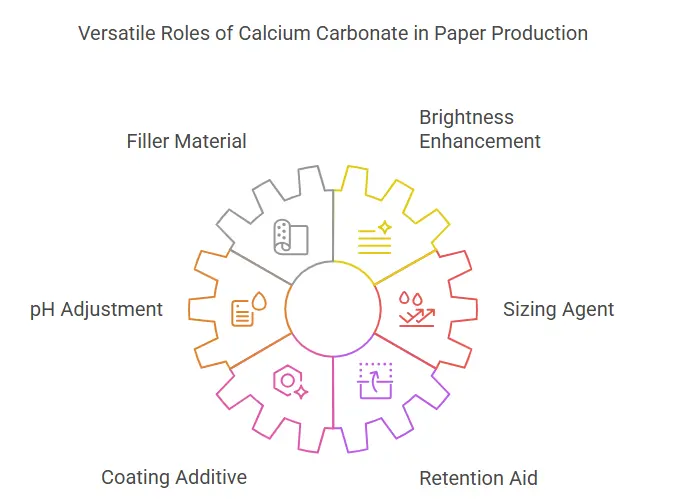

1. Filler Material:

In the paper industry, Calcium carbonate plays an important role as a filler material in paper production. When added to the paper mix, it helps increase the thickness and whiteness of the final paper. This allows manufacturers to use less of the expensive wood fiber without lowering the quality. In addition, calcium carbonate improves how well the paper handles ink by helping it absorb better and preventing ink from showing through the other side—something that’s key for sharp, clean printing.

2. Brightness Enhancement:

calcium carbonate also enhances paper brightness. It gives the paper a whiter, cleaner appearance, which boosts visual appeal. More importantly, increased brightness improves print contrast and readability, making documents and images stand out clearly. Therefore, calcium carbonate not only helps cut production costs but also ensures a superior printing surface.

3. pH Adjustment:

Calcium is utilized for pH adjustment in the papermaking process. It helps maintain the desired pH level of the paper pulp, which is crucial for optimal fiber retention, pulp stability, and the performance of other additives used in the process.

4. Sizing Agent:

Calcium carbonate functions as an effective sizing agent. It helps manage the paper’s surface characteristics, especially water resistance and ink absorbency. When applied properly, it enhances the sheet’s printability by minimizing ink feathering and promoting print results. Moreover, the improved water resistance adds durability to the paper. Thus, calcium carbonate contributes both to performance and print quality.

5. Coating Additive:

To achieve premium print quality, many paper manufacturers apply a coating layer made of pigment and binder. Calcium carbonate is commonly used in these coatings to enhance several surface properties. Specifically, it increases brightness, boosts opacity, and creates a smoother finish—ideal for high-resolution printing. Because of these improvements, coated papers deliver sharper images and clearer text, making them the preferred choice for magazines, brochures, and other high-end print products.

6. Retention Aid:

Calcium can act as a retention aid in the papermaking process. It helps improve the retention of fibers, fillers, and other additives in the paper pulp, thereby increasing the paper’s strength, quality, and formation.

Overall, calcium carbonate plays a vital role in the paper industry, providing benefits such as cost reduction, brightness enhancement, pH adjustment, sizing, coating improvement, calendering, and retention aid. Its versatile properties make it a valuable additive in paper production, contributing to the overall quality, aesthetics, and performance of various paper products.

To order send WhatsApp