No products in the cart.

6 Key Uses of Calcium Carbonate in the PVC Pipes industry:

Calcium carbonate is an essential ingredient in the production of PVC pipes, offering both performance and cost advantages. Its versatility makes it a popular choice for manufacturers across the industry. Below, we explore six practical uses of calcium carbonate in PVC pipe manufacturing.

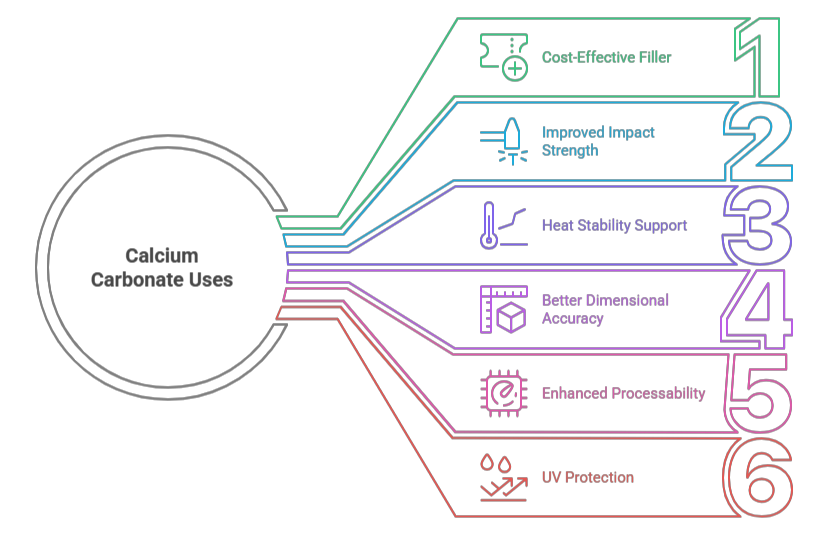

1. Cost-Effective Filler:

Calcium carbonate is commonly used as a filler to increase volume without significantly raising material costs. Since PVC resin is expensive, adding calcium carbonate allows manufacturers to produce thicker pipes using less resin—resulting in major cost savings.

2. Improved Impact Strength:

When blended into the PVC mix, calcium carbonate enhances the pipe’s resistance to impacts and mechanical stress. This added toughness is crucial in industries like plumbing and construction, where pipes must endure heavy loads and occasional impacts.

3. Heat Stability Support:

During manufacturing, PVC pipes are exposed to high temperatures. Calcium carbonate helps maintain the polymer’s strength and prevents degradation. As a result, the pipes retain their structural integrity during and after processes like extrusion and molding.

4. Better Dimensional Accuracy:

Pipes must retain their shape after cooling. Calcium carbonate improves dimensional stability by reducing shrinkage and warping. Therefore, manufacturers achieve consistent sizing and tight tolerances—important for proper pipe fitting and performance.

5. Enhanced Processability:

Another major benefit of calcium carbonate in PVC pipes is smoother processing. Calcium carbonate improves the melt flow of PVC, allowing for easier shaping during extrusion. This speeds up production and ensures uniformity in pipe thickness and length.

6. UV Protection:

For pipes used outdoors, exposure to sunlight is a concern. Calcium carbonate, when formulated properly, acts as a UV stabilizer. It helps prevent discoloration and extends the lifespan of the pipes under ultraviolet radiation.

In conclusion, calcium carbonate plays a key role in making PVC pipes more affordable, durable, and easier to produce. From improving mechanical properties to supporting environmental resistance, it remains a reliable additive for pipe manufacturers around the world.

To order send us WHATSAPP

Related Topics: The Most Important Uses of Calcium Carbonate in Various Industries